What makes a quality pair of cycling bib shorts and 3D printed Chamois pad?

Share

The Importance of a Quality Chamois Pad in Cycling Bibs: Why Transparency Matters

When it comes to cycling apparel, one of the most critical, yet often overlooked, components is the chamois pad in cycling bibs. The chamois pad is the part of the bib shorts that provides cushioning and support during long rides, ensuring comfort and preventing chafing. However, many cycling apparel brands keep the specifications of their chamois pads a mystery, leaving customers to guess the quality based on the price of the bibs. Unfortunately, price alone is not a reliable indicator of quality, and this lack of transparency can make it difficult for cyclists to choose the best gear for their needs.

Why Chamois Pad Quality Matters

The chamois pad plays an essential role in a cyclist's comfort. It’s designed to absorb shock, reduce pressure points, and wick away moisture, keeping you comfortable during long hours on the saddle. But the quality and construction of the pad can vary significantly, impacting your overall experience.

The problem is that many brands don’t disclose the exact specifications of their chamois pads, such as thickness, density, or the material composition. As a result, cyclists often rely on the price of the bib shorts as a proxy for quality, which is not always accurate. While high-end bib shorts tend to feature better chamois pads, price alone doesn't guarantee a superior experience.

Chamois Pad Manufacturers: What You Need to Know

Interestingly, many of the major cycling brands source their chamois pads from the same Italian companies, which are known for their high-quality materials and proprietary technologies. These companies, like Cytech or Elastic Interface, offer different models with varying levels of padding and design features, but each brand will add its own distinct touches to the pad’s composition and fit.

While there may be some differences between pads made by different manufacturers, the core technology and construction principles remain the same. This means that while two brands may use pads from the same manufacturer, the overall comfort and support can still vary significantly based on how the brand chooses to integrate the pad into their bibs.

3D Printed Chamois Pads: A Game-Changer in Cycling Comfort

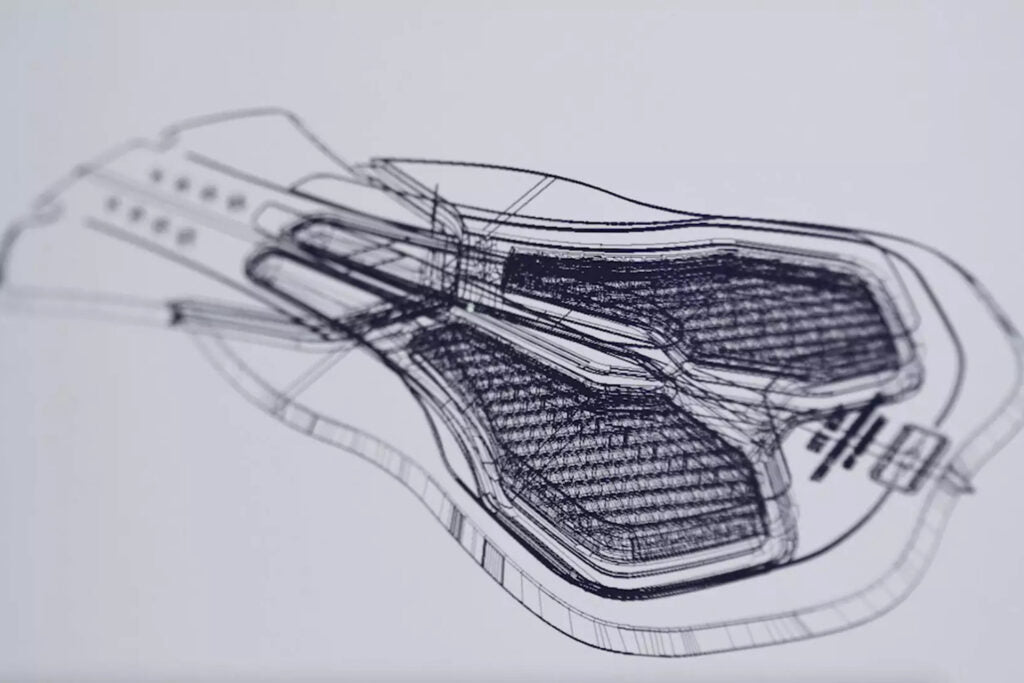

One of the most exciting developments in chamois pad technology comes from Elastic Interface, a leading manufacturer in the cycling apparel industry. Elastic Interface has pioneered the use of 3D-printed chamois pads, revolutionizing the way padding is designed and applied to cycling bibs.

Traditional chamois pads are made using multi-layered foam, but the 3D-printed chamois takes a much more precise and customizable approach. By using 3D printing, Elastic Interface is able to create a pad that offers tailored cushioning and optimized support where it's needed most, all while maintaining a lightweight structure. This technology allows for the precise adjustment of thickness, density, and shape, ensuring that every cyclist gets the most comfortable and supportive fit possible.

One of the major advantages of the 3D-printed chamois pad is its ability to mimic the natural contours of the body, providing customized pressure relief that traditional pads can’t match. The design also allows for better breathability and moisture-wicking properties, keeping you dry and comfortable during intense rides. These features not only improve comfort but also enhance performance by reducing fatigue and minimizing the risk of saddle sores.

Pad Thickness and Density: Key Factors for Comfort and Support

The thickness and density of the chamois pad have a direct impact on your riding comfort, support, and the expected duration of use. Here’s how these factors affect your ride:

-

Thickness: A thicker chamois pad generally offers more cushioning, which can be beneficial for long-distance rides or cyclists who experience more pressure points. However, too much thickness can cause discomfort by creating bulk and disrupting the natural fit of the bibs. Thicker pads tend to be used in longer rides where comfort is a priority, as they provide more padding for the saddle.

-

Density: The density of the chamois pad refers to how firm or soft the foam is. A high-density pad provides more support, reducing pressure on sensitive areas. It is particularly important for riders who log many hours in the saddle or ride aggressively. On the other hand, a low-density pad is softer and more comfortable for short rides but may not provide enough support for longer, endurance-focused rides.

Finding the right balance of thickness and density for your personal riding style and the type of cycling you do is essential for long-lasting comfort.

How the Chamois Pad Wears Out Over Time

Like any piece of cycling gear, the chamois pad will wear out over time, especially with frequent use. The materials inside the pad can break down, losing their shock-absorbing properties, leading to discomfort and reduced support. Even if the outer fabric of the bib shorts appears to be in good condition, the padding may no longer provide the same level of cushioning.

The rate at which the chamois pad wears out depends on several factors:

-

Frequency of Use: The more often you ride, the faster the chamois pad will degrade. Regular cyclists should pay close attention to the state of their pad, as it may start to lose its effectiveness after about 1-2 years of consistent use.

-

Quality of Material: Higher-quality chamois pads tend to last longer and maintain their shape and density better than lower-quality pads.

-

Washing and Care: Proper washing and care can help extend the life of your chamois pad. Avoid using harsh detergents, and wash your bib shorts with cold water to prevent the material from breaking down too quickly.

How Often Should You Replace Your Chamois Pad?

It’s essential to replace your chamois pad when you notice a decrease in comfort or support. As a general rule of thumb, a cycling bib with a high-quality pad should last between 1 to 2 years with regular use. However, if you’re using your bibs for several hours a week, or if you start experiencing discomfort on rides where you used to feel fine, it may be time to replace the bib shorts or the chamois pad.

Conclusion: The Need for Transparency in Chamois Pad Specifications

The chamois pad is one of the most important aspects of a cycling bib, yet many brands don’t provide detailed information about the pad’s specifications. Without this transparency, customers can only guess the quality based on price, which isn’t always an accurate indicator. By understanding the importance of factors like pad thickness, density, and wear, cyclists can make more informed decisions when purchasing bib shorts.

With the advent of 3D-printed chamois pads, brands like Elastic Interface are changing the game by offering customizable, optimized cushioning and support. These pads are a game-changer for comfort, performance, and durability, providing cyclists with the best possible experience. Brands should provide clear details about the chamois pads they use, including the material composition, thickness, and technology behind the pad. This transparency will help cyclists choose the right bibs for their riding style and ensure they get the most comfortable and durable product for their needs.